PROJECT SUMMARY

Name of Project

Stebbins Bulk Fuel Upgrades

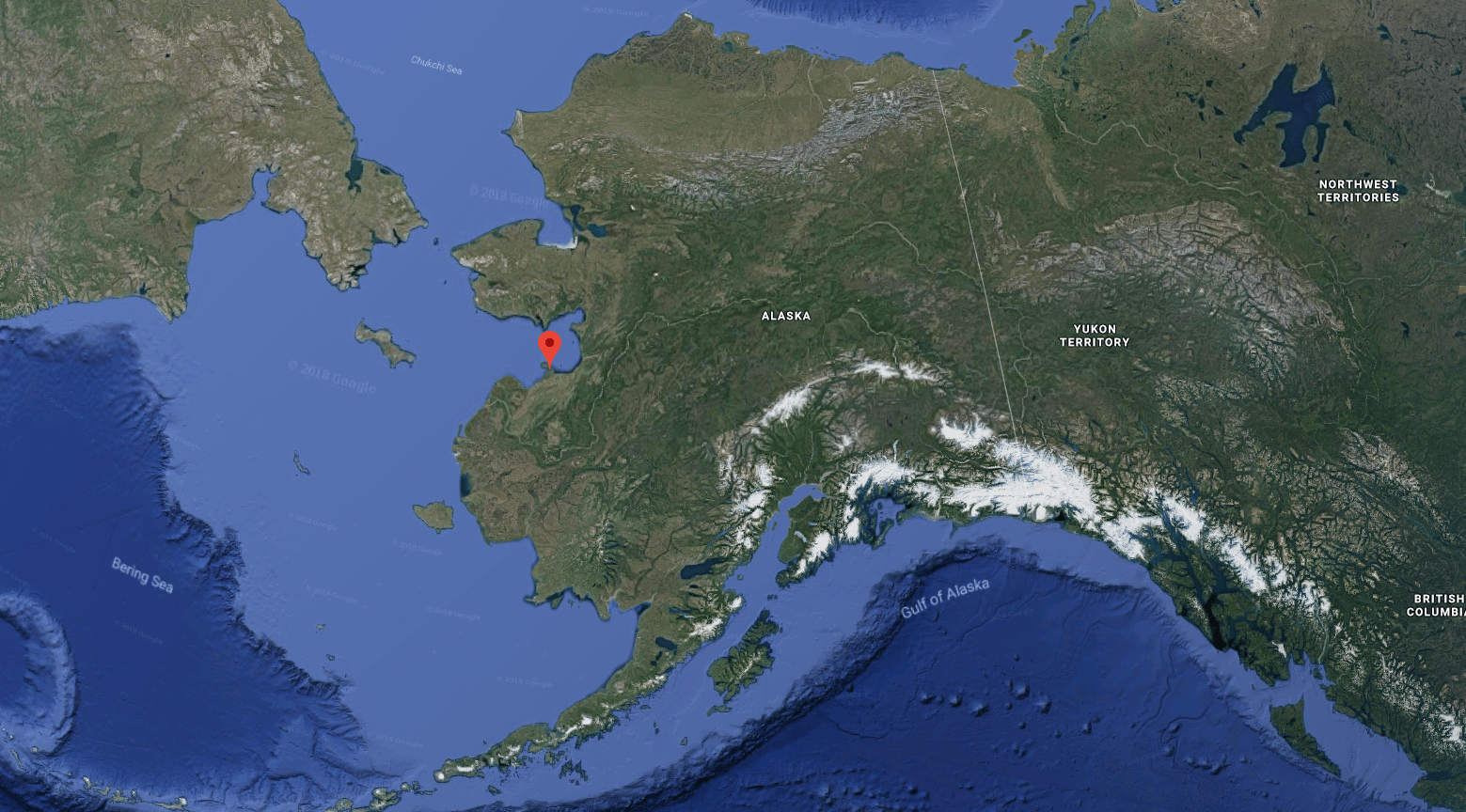

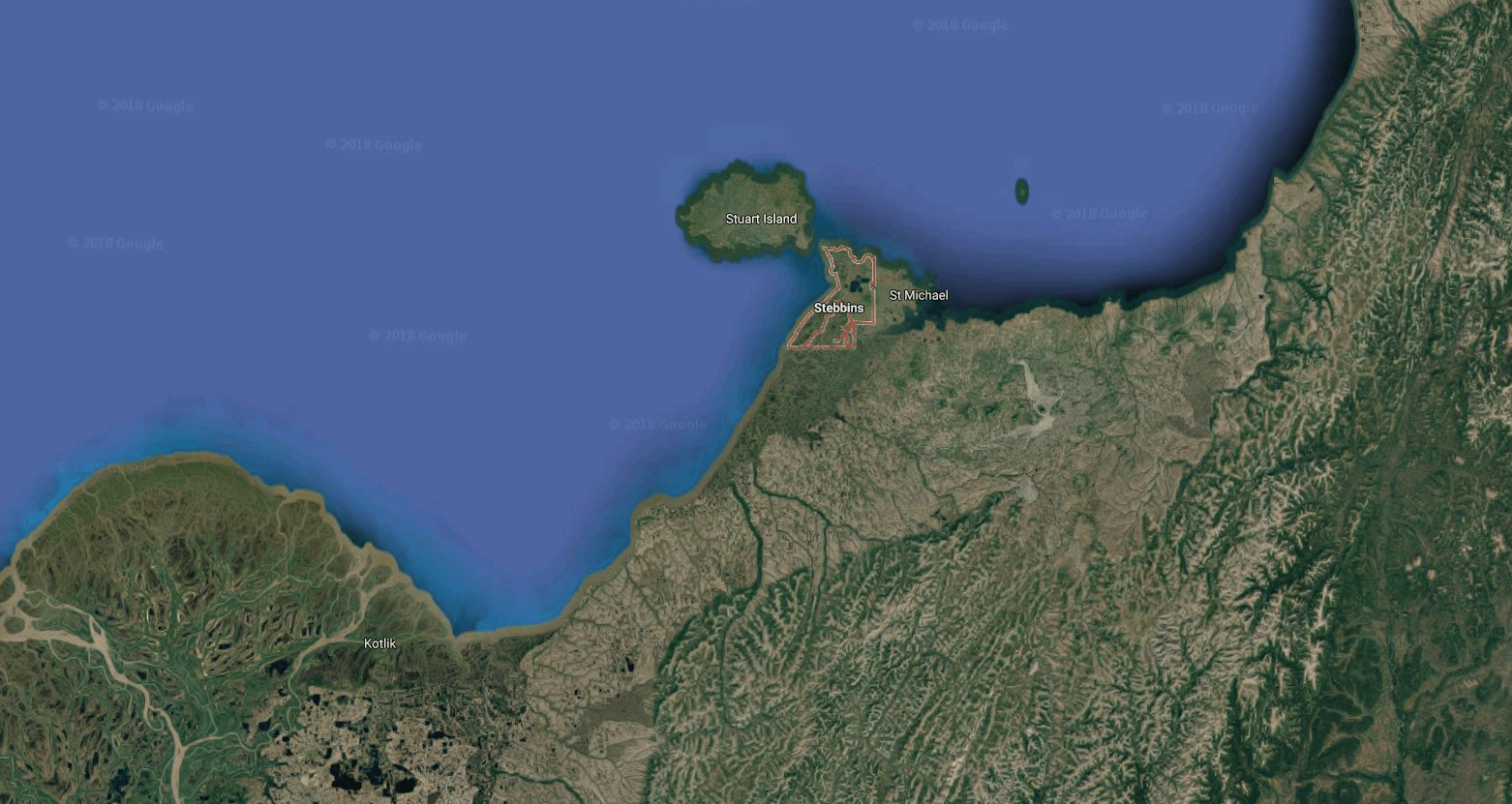

Location of Project

Stebbins, Alaska

Client

AVEC

Situation

The Village of Stebbins was in need of upgraded fuel storage facilities due to aging infrastructure. AVEC uses the fuel for power generation, the school uses it for heating and backup generation, and the community for retail sales.

Challenge

Like other coastal Alaskan communities, the soil profile of Stebbins is largely comprised of sand, silt, and sandy silt. This mixture of unstable substrate required the creation of access roads and pads, as well as the installation of pile foundations. Geotech data gaps at the beginning of the project led STG to encounter more difficult permafrost conditions than anticipated.

Solution

Due to our regional hub in Nome STG was able to bring in solutions for the pile driving challenges that would not have otherwise been economically feasible. As with most of our tank farm projects, STG installed all piping, fuel dispensers, and appurtenances in addition to setting the tanks using our in-house crane fleet. To keep the facility secure and well lit, STG installed security fencing and lighting. A containment area surrounds the 50,000-gallon capacity fuel tank in the event of a leak to protect the immediate area against contamination.

PROJECT SUMMARY

Name of Project

Stebbins Bulk Fuel Upgrades

Location of Project

Stebbins, Alaska

Client

AVEC

Situation

The Village of Stebbins was in need of upgraded fuel storage facilities due to aging infrastructure. AVEC uses the fuel for power generation, the school uses it for heating and backup generation, and the community for retail sales.

Challenge

Like other coastal Alaskan communities, the soil profile of Stebbins is largely comprised of sand, silt, and sandy silt. This mixture of unstable substrate required the creation of access roads and pads, as well as the installation of pile foundations. Geotech data gaps at the beginning of the project led STG to encounter more difficult permafrost conditions than anticipated.

Solution

Due to our regional hub in Nome STG was able to bring in solutions for the pile driving challenges that would not have otherwise been economically feasible. As with most of our tank farm projects, STG installed all piping, fuel dispensers, and appurtenances in addition to setting the tanks using our in-house crane fleet. To keep the facility secure and well lit, STG installed security fencing and lighting. A containment area surrounds the 50,000-gallon capacity fuel tank in the event of a leak to protect the immediate area against contamination.