PROJECT SUMMARY

Name of Project

CD-5 Colville Delta Bridge

Location of Project

North Slope, Alaska

Client

Ruskin

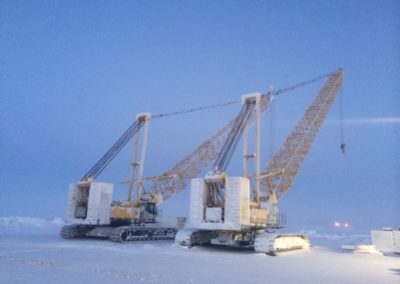

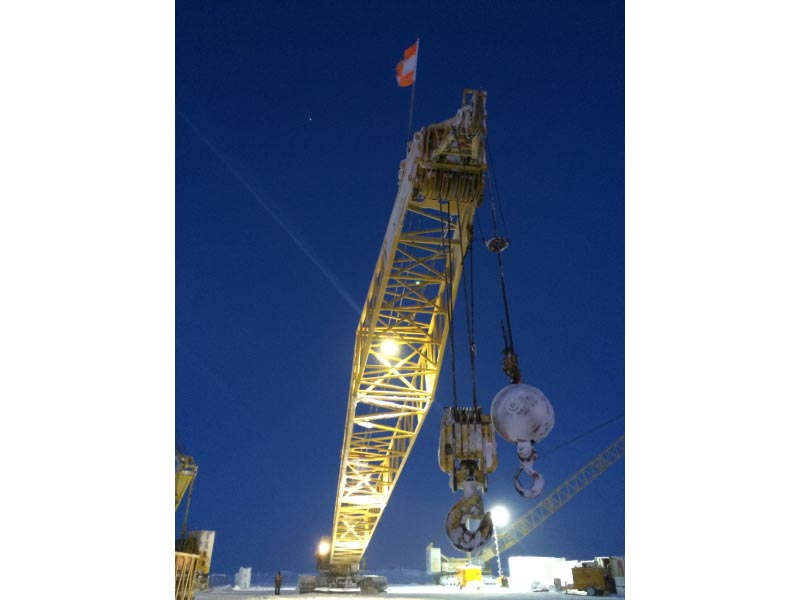

Situation

A bridge was needed to span the Colville River connecting the CD-5 and Alpine Fields.

Unique Challenges

Winter time conditions included extreme cold weather and darkness. Temperatures commonly reach minus 40 degrees and there was 24-hour darkness in this far-north location.

Solution

In winter 2013, STG sent several cranes and pile driving equipment to Alaska’s North Slope to assist in the construction of a bridge through the Colville Delta (CD-5). In all, STG deployed five cranes, two vibratory hammers, and one impact hammer to ConocoPhillips’ general contractor.

Before the cranes and pile driving equipment were sent up north, STG ensured that all machinery was properly weatherized to withstand the arctic conditions. This meant removing and upgrading all hoses and fluids to meet a temperature rating of -70 degrees Fahrenheit. Hydraulics, engines, oil tanks, radiators, and crane cabs were all retrofitted with some combination of heater coils, heater pads, circulating pumps, or blankets to help maintain operation in the arctic temperatures. Boom lights were also added to each crane for improved visibility.

PROJECT SUMMARY

Name of Project

CD-5 Colville Delta Bridge

Location of Project

North Slope, Alaska

Client

Ruskin

Situation

A bridge was needed to span the Colville River connecting the CD-5 and Alpine Fields.

Unique Challenges

Winter time conditions included extreme cold weather and darkness. Temperatures commonly reach minus 40 degrees and there was 24-hour darkness in this far-north location.

Solution

In winter 2013, STG sent several cranes and pile driving equipment to Alaska’s North Slope to assist in the construction of a bridge through the Colville Delta (CD-5). In all, STG deployed five cranes, two vibratory hammers, and one impact hammer to ConocoPhillips’ general contractor.

Before the cranes and pile driving equipment were sent up north, STG ensured that all machinery was properly weatherized to withstand the arctic conditions. This meant removing and upgrading all hoses and fluids to meet a temperature rating of -70 degrees Fahrenheit. Hydraulics, engines, oil tanks, radiators, and crane cabs were all retrofitted with some combination of heater coils, heater pads, circulating pumps, or blankets to help maintain operation in the arctic temperatures. Boom lights were also added to each crane for improved visibility.